Introduction

LiteZone Glass Inc. manufactures LiteZone®, a next generation, award winning, ultra energy efficient insulating glass unit that makes possible the world’s most energy efficient and longest lasting windows. LiteZone® insulating glass is available for sale to home owners, commercial building owners, builders, renovators, glazing contractors, as well as window and curtain wall manufacturers, and to anyone else wishing to purchase truly high performance and long lasting insulating glass.

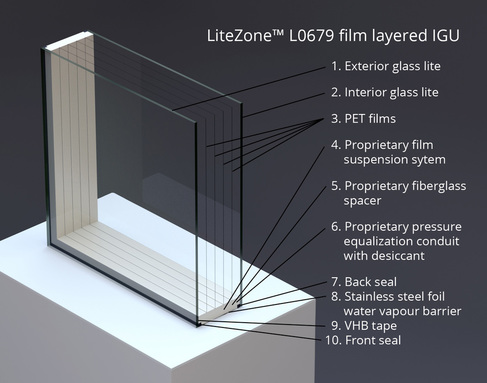

Construction

The basic construction of a LiteZone® insulating glass unit (example of 6 layered unit with ~R17 centre of glass):

- Exterior glass lite, a low-e or other coating/tinting is optional;

- Interior glass lite, a low-e coat is optional;

- Between 1 and 8 intermediate layers of PET films; the number of films and the use of low-e coats on those films is optional depending on the performance required;

- Proprietary film suspension system;

- Proprietary fiberglass spacer; the spacer width varies to allow for more or fewer films;

- Proprietary pressure equalization conduit with desiccant;

- Back seal is structural silicone/SS foil/polyisobutylene;

- Stainless steel (SS) foil water vapour barrier around the entire perimeter of the glass unit;

- Very High Bond (VHB) structural tape is used to attach the glass to the spacer;

- Front seal is structural silicone/SS foil/polyisobutylene;

- The internal cavities are air filled only and pressure equalized.

Minimizes Weight

LiteZone® minimizes the weight of multi-layered insulating glass units. The PET films used within a LiteZone® glass unit have negligible weight and are inexpensive compared to glass. Up to 8 intermediate layers of films are used to configure LiteZone® insulating glass units to achieve very high insulating values with a minimal increase in weight and on a cost effective basis. Because of the extra glass lite, the glass in triple pane IGUs weigh 50% more than the glass in LiteZone® IGUs. After allowing for the extra weight of the LiteZone® fiberglass spacers, in 5' x 8' glass units, triple pane IGUs weigh approximately:

- 40% more than LiteZone® L0479 glass units (2 films) that have about 25% higher window insulating values;

- 35% more than LiteZone® L0679 glass units (4 films) that have about 80% higher window insulating values; and

- 22% more than LiteZone® L1079 glass units (8 films) that have about 250% higher window insulating values.

The extra weight of triple pane windows can make handling them more difficult compared to windows using LiteZone® glass units.

Air filled

LiteZone® is air filled and has no concerns with loss of performance or becoming decompressed due to escaping argon. Insulating values can be increased by filling conventional glass units with a low conductive gas such as argon, krypton or xenon. Because of the very high cost of krypton and even higher cost of xenon, the most common gas used is argon. Gas filled glass units are known to have issues with the gas escaping through the edge sealants over time. Tiny flaws in an edge seal can result in the gas escaping very quickly. Even with perfect edge seals, argon will escape at the rate of about 1% per year. With a starting point of a 90% fill level (an industry standard), the performance of gas filled glass units will significantly degrade over its life. This can be a serious problem for buildings with heating and cooling systems dependent on the performance of its windows.